In this colorful world, there is a metal that combines resilience and elegance, able to withstand the erosion of harsh environments while playing a pivotal role in modern life – it is the protagonist of our story today – 304 mea inisiua. So, what are the mysterious meatotino o 304 uamea stainless? Let’s embark on this journey of exploration together!

Properties of 304 Stainless Steel – 304 Stainless Steel’s Corrosion Resistance

Tasi o le sili taua meatotino o 304 uamea stainless is its excellent corrosion resistance. This property makes it highly suitable for use in harsh environments and industries such as chemical processing, food processing, and marine applications.

The corrosion resistance of 304 stainless steel can be attributed to the presence of chromium (18-20%) and nickel (8-10.5%). These elements react with oxygen in the air or water, forming a thin layer of oxide on the surface that serves as a barrier to prevent further oxidation or rust.

In addition, this type of stainless steel contains a small amount of molybdenum (2-3%) that enhances its resistance to pitting and crevice corrosion. Pitting occurs when local areas on the surface are damaged, exposing the underlying metal to corrosive substances, while crevice corrosion is caused by deposits trapped in the gaps between the surface.

Furthermore, 304 stainless steel may undergo sensitization when exposed to temperatures above 800°F (427°C), leading to intergranular corrosion. Therefore, proper heat treatment after welding or machining is crucial to maintain optimal performance.

Due to its excellent resistance to various types of corrosion attacks, 304 stainless steel remains a popular choice for many industries where durability and reliability are top priorities.

Thermal Processing of 304 Stainless Steel

Thermal processing is a technique used to modify the physical and mechanical meatotino o 304 uamea stainless under high-temperature conditions. This process involves heating the material to a specific temperature, maintaining it at that temperature for a certain period of time, and then cooling it in a controlled manner.

Two commonly used thermal processing methods for 304 stainless steel are annealing and quenching. Annealing involves heating the steel to approximately 1,900°F (1,038°C) and maintaining it at that temperature for a relatively long period of time, then gradually cooling it in a furnace. This process helps relieve internal stresses within the metal structure and increase its ductility.

Quenching is another method where the metal piece is heated to a red-hot state and then rapidly immersed in water or oil. This process creates a hardened surface layer on the exterior while maintaining some degree of flexibility within the material.

It is important to note that overheating can cause irreparable changes to the microstructure, leading to embrittlement even with the application of minimal force. Appropriate thermal processing can enhance mechanical strength and corrosion resistance levels when properly done without adverse effects on other properties.

Talosaga o le 304 Stainless Steel

304 stainless steel is a versatile alloy with excellent corrosion resistance, suitable for various applications in different industries. Its combination of strength, durability, and ease of manufacturing makes it an ideal choice for many products.

-

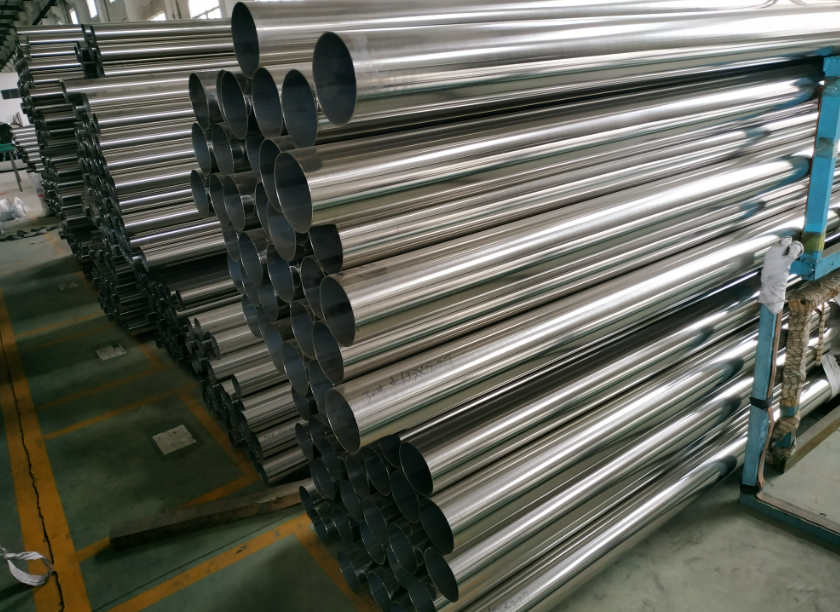

- One of the main uses of 304 stainless steel is in manufacturing. The alloy’s high rust resistance and anti-pollution properties make it very suitable for producing equipment that needs to withstand harsh environmental conditions without degrading over time, such as storage tanks, pipelines, valves, and fittings.

- In addition to manufacturing, 304 stainless steel is widely used in the food processing industry. Its non-reactivity makes it very suitable for handling acidic foods or liquids containing salt or vinegar.

- Another common use of this alloy is in construction projects, where its strength and corrosion resistance make it very suitable for building structures such as bridges, railings, and other outdoor fixtures exposed to weather factors like rain or marine spray.

- The healthcare industry also heavily relies on 304 stainless steel because of its biocompatibility, which helps prevent contamination during medical procedures. Therefore, surgical instruments made from this material can be repeatedly sterilized without corroding or degrading over time.

Because 304 stainless steel has numerous advantages over other materials like aluminum or carbon steel when used correctly, manufacturers will continue to use 304 stainless steel as customer satisfaction remains paramount.

iʻuga

Faafetai mo le faitauina o la matou tusiga ma matou te faʻamoemoe e mafai ona fesoasoani ia te oe e maua ai se malamalama sili atu i le meatotino o 304 uamea stainless. Afai e te manaʻo e suʻe nisi faʻamatalaga e uiga i le 304 stainless steel, matou te fautuaina oe e asiasi Sino uamea uamea.

I le avea ai ma taʻutaʻua faʻatau oloa o oloa uʻamea i le lalolagi atoa, Sino uamea uamea tu'uina atu i tagata fa'atau oloa oloa u'amea maualuga maualuga e pei o 316L and 316 Hot Rolled Stainless Steel Plate, Uamea uamea Fa'atau, Ala uamea uamea, 201 Stainless Steel Strips & 304 uamea uamea fasi, 430 Papatusi Uamea, Uamea uamea Hexagon Pa, u'amea fa'amea vevela, Pepa u'amea u'amea lanu, u'amea sa'o sa'o ta'ai malulu, Uaea uamea, ma Papatusi u'amea uamea fa'amau.

: +86-18621535697

: +86-18621535697  : export81@huaxia-intl.com

: export81@huaxia-intl.com